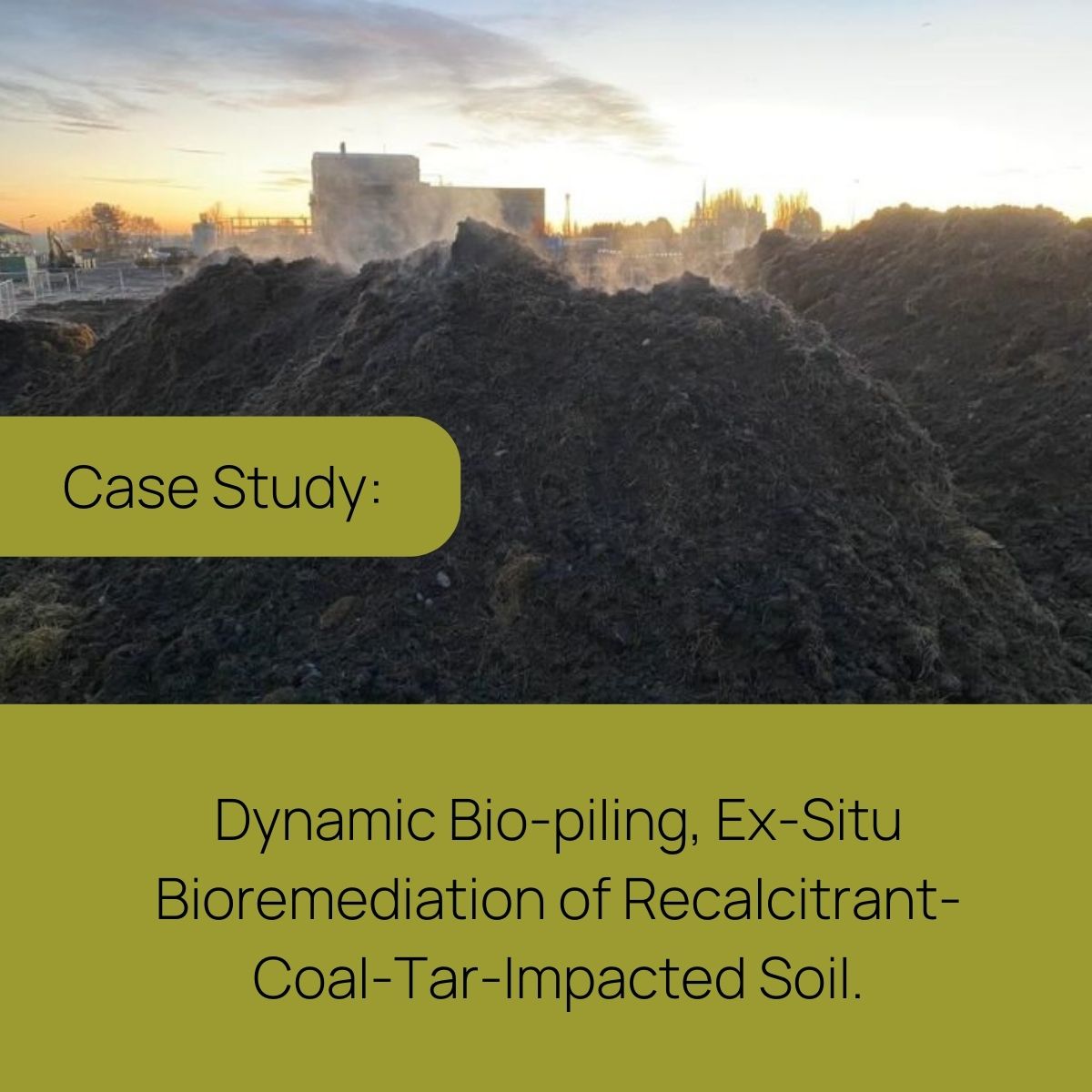

Ex-situ bioremediation of recalcitrant-coal-tar-impacted soil using patented Dynamic Biopiling

North East England, UK

The treatment of gross, NAPL-saturated, gasworks waste presents a significant technical challenge. Many treatment options such as soil washing, or thermal desorption offer little commercial benefit against offsite disposal and offsite options are often much less sustainable and more expensive.

Design Innovation

Following more than 20 years of research and development, EESI have developed a novel, patented, ex-situ bioremediation process designed for the treatment of complex, high concentration, hydrocarbon impacts to soil under the banner of Dynamic Biopiling. Using our Dynamic Biopiling techniques, we have successfully treated hundreds of thousands of tonnes of soils impacted with NAPL coal tar, crude oil and pesticides over the past two decades.

Brilliant Bacteria

Dynamic Biopiling is based on the principals of chemically and geotechnically improving the soil environment to maximise contaminant bioavailability concurrent to the promotion of the growth and activity of indigenous soil bacteria. Soil conditioning comprised solid and liquid additives, including the addition of in-house proprietary surfactants, solvents and nutrients, mixed into the soil using a Mobile Unit for Soil Treatment (MUST). Our MUSTs provide three stages of high intensity mixing, combining both solid and liquid amendments deep into the soil matrix.

Saturated to Safe

Following an invitation by National Grid, the first major use of Dynamic Biopiling technology in the UK was at the former Clough Road Gasworks in Hull. Working as a sub-contractor, EESI Remediation successfully deployed this innovative ex-situ bioremediation method for the treatment of approximately 70,000 tonnes of grossly impacted soil at the former Clough Road Gasworks, Hull.

At this site, tarry soil typically containing very high concentrations of PAH and TPH compounds and phase separated NAPL were hauled to a designated treatment area by the main contractor. Segregation of these materials was typically based on visual and olfactory field assessment with less contaminated soil being sent to another contractor for conventional ex-situ bioremediation treatment. Material sent to the EESI treatment area was typically sourced from historically infilled tar distillation tanks, source hotspots and other retaining features that were impacted with coal tar.

A Closer Look at Biodegradation

Following an initial primary maturation period where labile contaminants rapidly biodegraded, the further addition of pre-conditioned organic matter, nutrients, green solvents and biosurfactants was completed to increase contaminant bioavailability and promote co-metabolic biodegradation. Between intensive soil conditioning using the MUST, soils were turned and mechanically aerated using excavators where the open structure of the conditioned soil supported optimal air exchange and moisture regulation. All 60,000 tonnes of soil were treated over a 15-month operational period.

Sustainable Practices

The complexities of ex-situ biodegrading high concentration organic contaminants extends beyond the treatment process, as these materials are typically highly odorous and prone to excessive leaching. To address the potential impact to the environment, EESI has developed a four-tier range of control measures that move from practical measures to reduce contaminant release through to the establishment of enclosed and contained environments. At the Clough Road project, we deployed tier four measures that included the use of our atmosphere controlled 150m x 50m temporary enclosure. This measure removed the potential for odour impact and also allowed uninterrupted treatment over a 15 month period.

EESI have deployed Dynamic Biopiling at more than 20 sites, treating in excess of 350,000 tonnes of grossly impacted soil. Dynamic Biopiling has also been deployed in the UK to treat other contaminants, including heavy end hydrocarbon fuels and pesticides.

Wed Like to Hear From You.

Enter your email address and receive a first-look at our unique BioPiling innovation.